Over 80% of the farm's electrical demand is met by on site solar panels, which are intertied with the utility grid.

A 1950's era gas powered Allis Chalmers Model G has been converted to run off of a bank of batteries.

The Model G batteries are recharged from solar panels, making this tractor a solar powered tractor.

An electric fence used to keep chickens out of our crops is charged by a solar panel.

It takes a lot of diesel and air emissions to get our produce to market. We mitigate the impact by seeking out high efficiency vehicles. The Sprinter on the right gets 18 mpg while the Isuzu on the left only gets 14 mpg.

We limit our highway speeds to 55 mph in order to conserve fuel and reduce emissions. Generally, this creates a 15% fuel savings per mile, and a similar reduction in greenhouse gas emissions, when compared to a vehicle going 65 mph. EPA test results show that light duty gas powered vehicles traveling at 55 mph create substantially less emissions than when the same vehicle travels at 65 mph: nitrous oxides are reduced by 8% per mile, volatile organic compounds decreases 35% per mile, and carbon monoxide declines 60% per mile.

A fleet of zero emission bicycles provide on farm transportation for our workers. The bicycle is surely one of the most useful and efficient technologies ever created.

Lighting in all our buildings is provided by fluorescent light bulbs. As these bulbs die we intend to replace them with LEDS for greater energy savings and longer bulb life.

The last, lonely incandescent on the farm was removed in 2011.

A high efficiency motor powers this irrigation pump.

Diesel fuel used in our tractors and trucks accounts for a large share of the farm's emissions, making for a vexing challenge in the pursuit of carbon-free energy. In the blackberries behind the diesel tank is an old barn that collapsed within a year of our arrival on the land. Common practice would be to burn the remaining wood to get it out of the way. However, this option means that our garbage would become our neighbors garbage and contribute to global warming. So the barn slowly rots into the ground.

Our greenhouse is a major source of heat loss. We put up insulated walls every Fall. The walls are removed in the late spring to allow for better ventilation.

This air shutter allows fresh air into the greenhouse on warm days. The insulated doors are closed at night to prevent heat loss. The wooden end walls, surrounding the shutters, are also insulated.

A fan constantly blows air between the two layers of plastic forming the roof of the greenhouse. The air between the plastic layers provides some insulation and extends the life of the plastic by making it less vulnerable to wind.

Water pipes deliver heat to the bottom of plant trays in the greenhouse. This is a far more efficient way of giving the plants the warmth they need than the air heater we used to use.

A tankless water heater in the greenhouse heats the water that warms the plants. It heats water only as it is needed rather than maintaining the temperature in a hot water tank even when it is not being used.

The greenhouse water heater is propane fueled. We plan to stop using this nonrenewable resource by installing a heat pump powered by electricity from solar panels.

The underground pipes that deliver the hot water from the greenhouse water heater to the plant tables are insulated with foam to prevent heat loss to the ground.

A natural source of heat for the greenhouse.

Motor oil is purchased in reusable drums rather than nonrecyclable plastic containers. These buckets on the floor hold used oil that is waiting for transport to a recycling facility.

Used oil filters are stored in a barrel before being transported to a Portland company that separates and recycles the steel, paper, and oil in the filters. It takes ten years to fill this barrel!

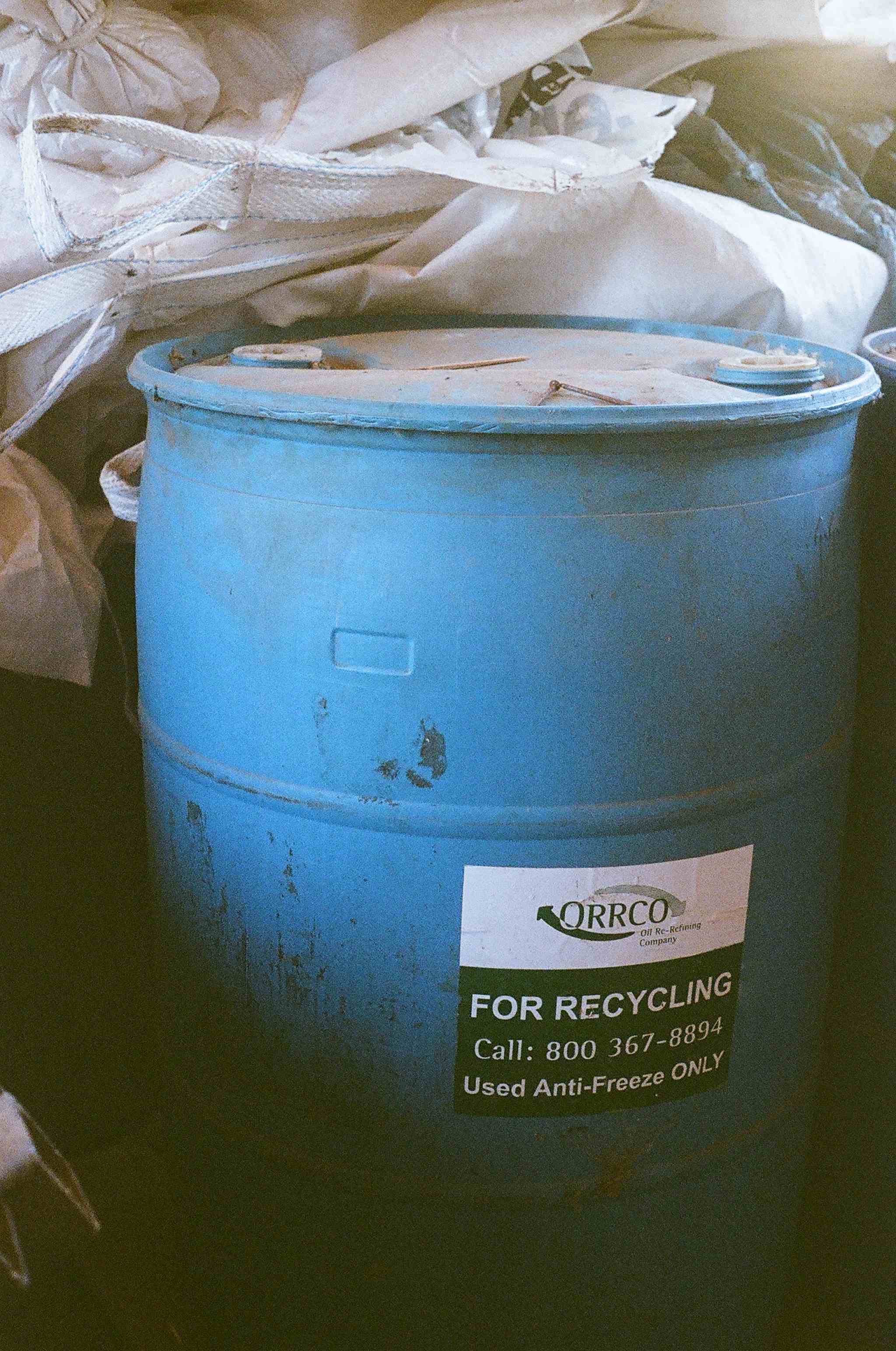

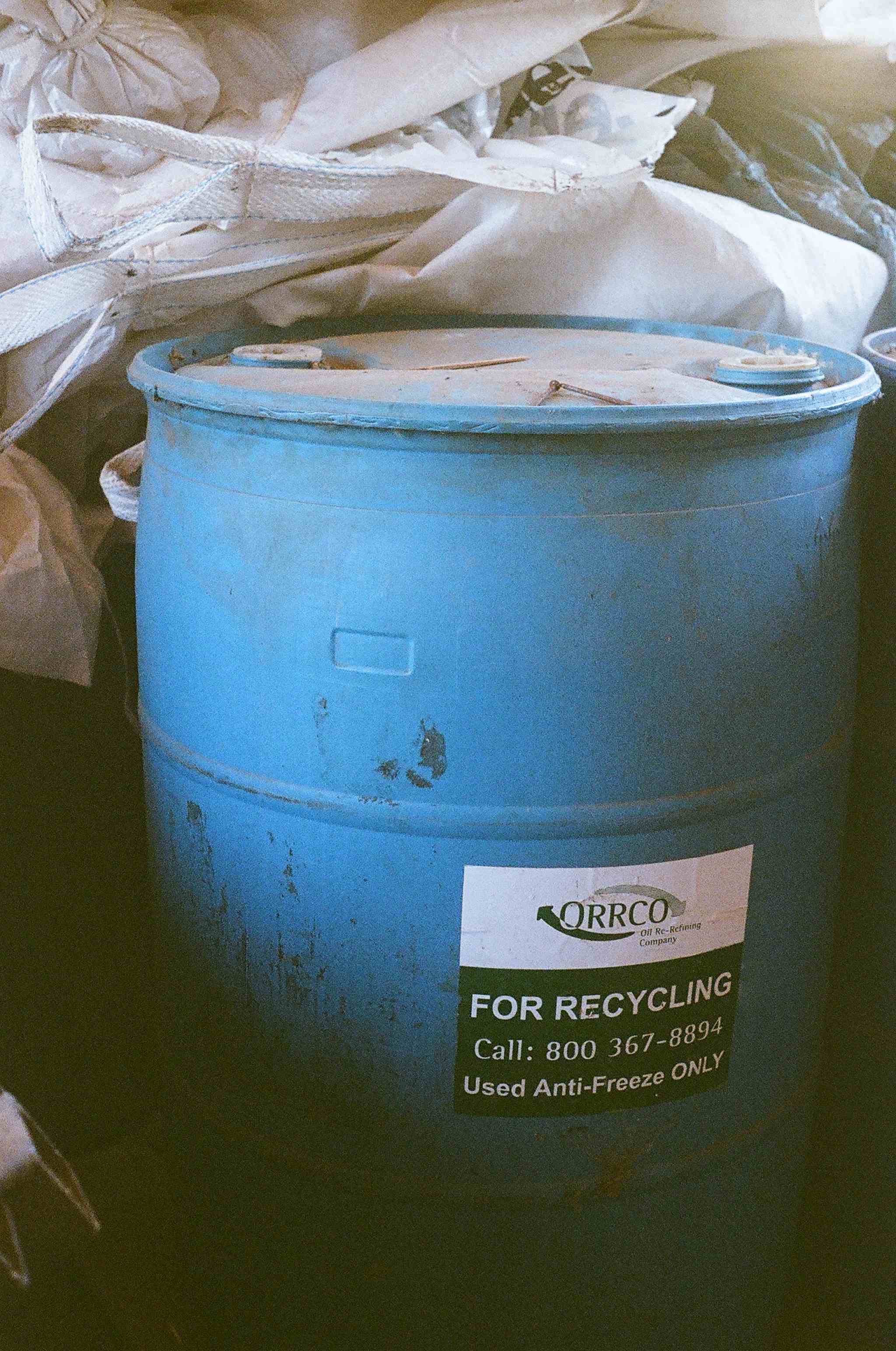

Used anti freeze is stored in a barrel before transporting it to a recycling facility.

One of several recycling stations on the farm for storing used paper, glass, metal, and plastics before transport to a recycling facility.

Used metals are stored in barrels and taken to a junkyard annually for recycling.

Old pallets and wood scraps accumulate and rot into the soil rather than being burned.

Any wood scraps that contain chemicals, such as paint on the glue used in plywood, are sent to a scrap wood processing facility where they are chipped and used as fuel for industrial processes.

While we strive to minimize plastic usage by not using it for mulch or hoophouses (for indoor produce production) we still generate plastic waste in the form of plant trays, produce boxes, and tarps such as the one covering a compost pile. Some used plastics can be "down cycled," meaning it cannot be recycled into its original form but it can be made into a lower grade material, such as plastic lumber. Other plastics have to go to landfills.

We believe that an important part of sustainability is to challenge obsolescence by using items until they are worn out. Many people regard rotary phones as outdated, but this one is still serving us after 30+ years of use.

The two cylinders leaning against the post are fish screens that we use on our irrigation pump intake to keep fish of all sizes from getting sucked into the irrigation system.